📌 Introduction: Most Test Failures Are Not Equipment Failures

Even when using high-quality tensile testing equipment, labs often experience inconsistent results—unstable force curves, unexpected break locations, or poor repeatability. These issues may look like machine defects, but in most cases, they’re caused by small but critical setup or operation errors.

In this article, we’ll cover the 5 most common sources of tensile test errors and offer clear, actionable steps to fix them—without replacing your machine.

1️⃣ Grip Slippage or Poor Clamping Force

📌 Symptoms:

- Sample slips during the test

- Sudden drop in load reading

- No clear break point in force curve

🔍 Likely Causes:

- Improper grip selection

- Insufficient clamping pressure

- Worn or smooth grip faces

✅ Fixes:

- Use serrated, rubber-coated, or pneumatic grips depending on material

- Replace worn jaw inserts

- Increase grip contact area or insert anti-slip layers

2️⃣ Off-Center Breaks or Out-of-Gauge Failures

📌 Symptoms:

- Specimen breaks near the grip instead of the center

- Test report becomes invalid due to non-gauge fracture

🔍 Likely Causes:

- Misalignment during clamping

- Uneven clamping force

- Inconsistent sample geometry

✅ Fixes:

- Use alignment fixtures or centering tools

- Ensure symmetrical and gradual clamping

- Verify sample preparation per ISO/ASTM dimensions

3️⃣ Force Value Instability or Load Fluctuations

📌 Symptoms:

- Force readings are erratic or jump unexpectedly

- Load curve shows noise or irregular steps

🔍 Likely Causes:

- Loose sensor cables

- Platform vibration interference

- Sampling frequency too low

✅ Fixes:

- Tighten sensor connectors and verify grounding

- Use a vibration-isolated platform

- Increase software sampling rate or enable filtering

4️⃣ Elongation Measurement Errors

📌 Symptoms:

- Stretch values vary too widely between tests

- Unusual strain curves or negative elongation detected

🔍 Likely Causes:

- Incorrect gauge length setting

- Zeroing performed after load is applied

- Optical extensometer out of calibration

✅ Fixes:

- Set gauge length accurately before starting

- Apply light preload before zeroing

- Recalibrate or verify extensometer accuracy

5️⃣ Poor Repeatability Across Tests

📌 Symptoms:

- Same material, same machine, but inconsistent results

- High variance in tensile strength or yield points

🔍 Likely Causes:

- Operator inconsistency

- Environmental variation (temperature, humidity)

- Non-uniform sample preparation

✅ Fixes:

- Establish clear SOPs for all operators

- Precondition specimens in a controlled environment

- Use calibration-grade reference materials

📚 International Standards Support

Common tensile test errors are addressed in most international testing standards. Adhering to proper setup and execution helps ensure both data accuracy and regulatory compliance.

✅ Final Thoughts: Don’t Blame the Machine—Fix the Method

Tensile testing errors don’t always mean your equipment is faulty. More often, small process flaws create big data problems. By understanding and addressing the root causes of common issues, you can dramatically improve the quality and reliability of your testing process.

📞 Need help with alignment, grips, or test setup? Our team offers free technical guidance for users of tensile testing equipment in labs, R&D centers, and universities worldwide.

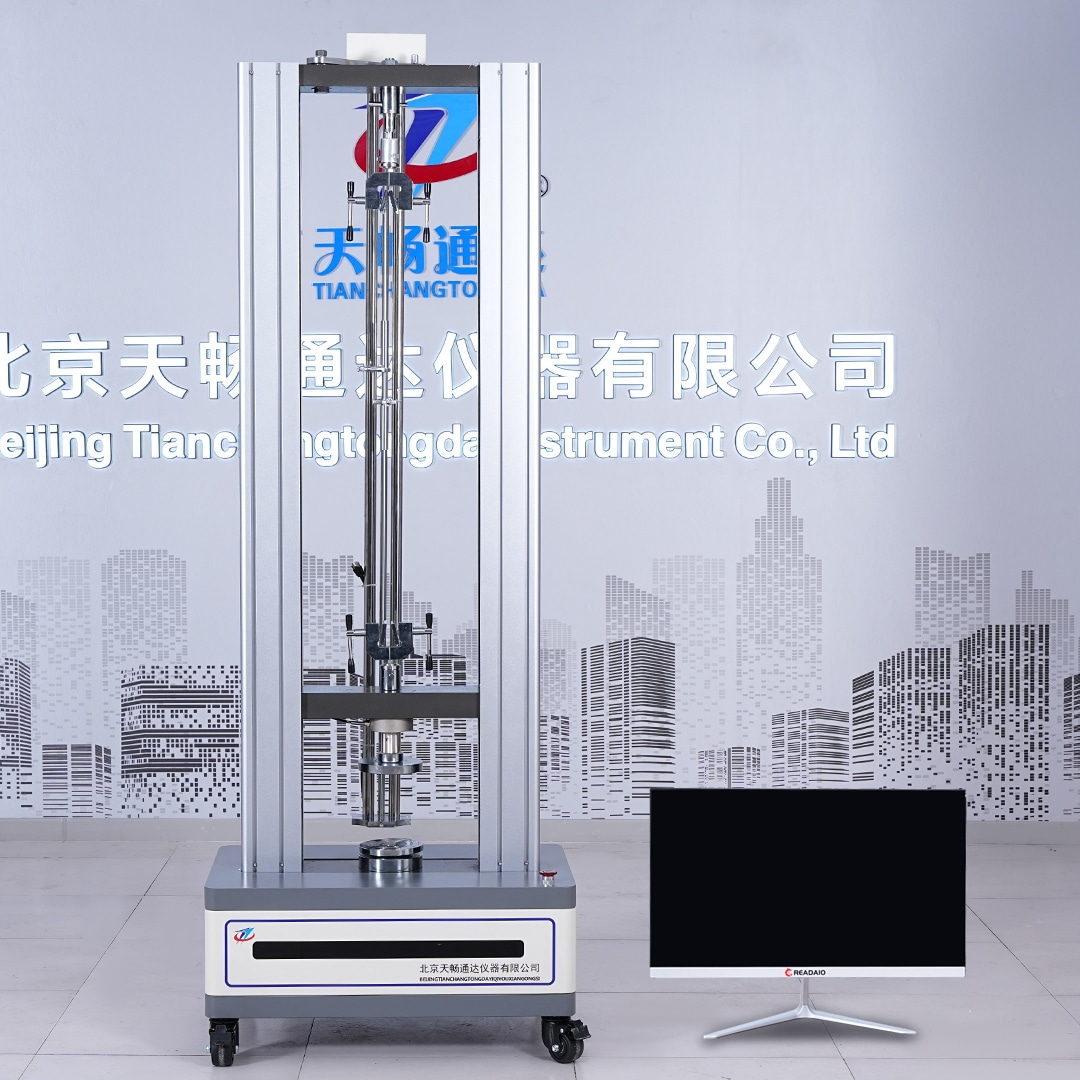

Lab-grade tensile testing equipment with intelligent software, interchangeable grips, and high sampling accuracy. Ideal for plastics, rubber, and composite testing.

🔍 View Tensile Testing Equipment Product Details