📌 Introduction: What’s Inside a UTM Machine Actually Matters

A UTM machine—short for Universal Testing Machine—is a powerful tool used for evaluating the mechanical properties of materials such as tensile strength, compressive strength, or flexural resistance. But how does it actually work? What makes one UTM more reliable than another?

Understanding the core structure and working mechanism of a UTM machine gives you a clear edge when selecting the right model, operating it correctly, or troubleshooting unusual test results. In this guide, we break down how a UTM machine functions and explain its major components in a way that’s both technical and practical.

🔁 How Does a UTM Machine Work?

At its core, a UTM machine applies a controlled mechanical load to a specimen and records how the material reacts to that force. Here’s how the process works:

- A motor-driven crosshead moves vertically to apply tensile or compressive force.

- A high-precision load cell measures the real-time force exerted on the specimen.

- A displacement system records elongation or compression.

- The controller ensures constant velocity and consistent loading behavior.

- The software collects data points and generates stress–strain or force–displacement curves.

📎 In modern systems, all of this is fully automated and programmable through PC-based control software.

🧱 Main Component #1: Frame System

The structural frame determines the maximum force capacity, rigidity, and test stability of the UTM.

- Single-column frames are compact, suitable for low-force tests (1kN–5kN)

- Dual-column frames offer high rigidity for larger loads (10kN–600kN+)

- Movable crosshead adjusts to accommodate different sample lengths

✅ A high-quality frame ensures no mechanical deflection occurs during testing, preserving accuracy.

⚖️ Main Component #2: Load Cell (Force Sensor)

The load cell is the heart of the UTM—it determines the accuracy and reliability of your test results.

- Available in different ranges (e.g., 1kN, 2kN, 5kN, 10kN…)

- Usually ±0.5% or ±1% accuracy (ISO Class 0.5 / Class 1)

- Interchangeable or dual-range for versatile applications

✅ Without a certified load cell, your test data cannot be validated by international standards.

⚙️ Main Component #3: Drive System

The drive system moves the crosshead and creates the load.

- Most modern UTMs use servo motors or stepper motors

- Motion is transferred via ball screws or lead screws

- Controls test speed, preload, and displacement rate

Typical testing speed ranges from 0.01 mm/min to 500 mm/min, depending on test standards and materials.

✅ A stable, vibration-free motion system ensures clean and repeatable data.

💻 Main Component #4: Control & Software System

This is where the test becomes intelligent.

- Select test types (tensile, compression, flexural, shear, etc.)

- Set parameters: gauge length, speed, limit conditions, break criteria

- Real-time graph plotting: stress–strain or force–displacement

- Exportable reports: PDF, Excel, CSV

- Multi-language UI (including English), standard templates for ASTM/ISO tests

✅ Powerful software turns raw force data into actionable quality reports.

📚 Standards and Verification

To be trusted in research, production, or third-party testing, your UTM machine must comply with recognized international standards.

Here are two key standards governing verification of force and measurement systems:

📎 Both standards require annual calibration and traceability to national metrology institutes.

✅ Final Thoughts: Know Your Machine Before You Trust the Results

When you understand how a UTM machine works, you’re no longer just pressing “Start”—you’re interpreting your data with context and confidence. Knowing what’s inside helps you choose better models, detect problems faster, and meet testing standards with no compromise.

📞 Want help selecting the right force range or components for your application? Our engineering team offers free consultation and model recommendations.

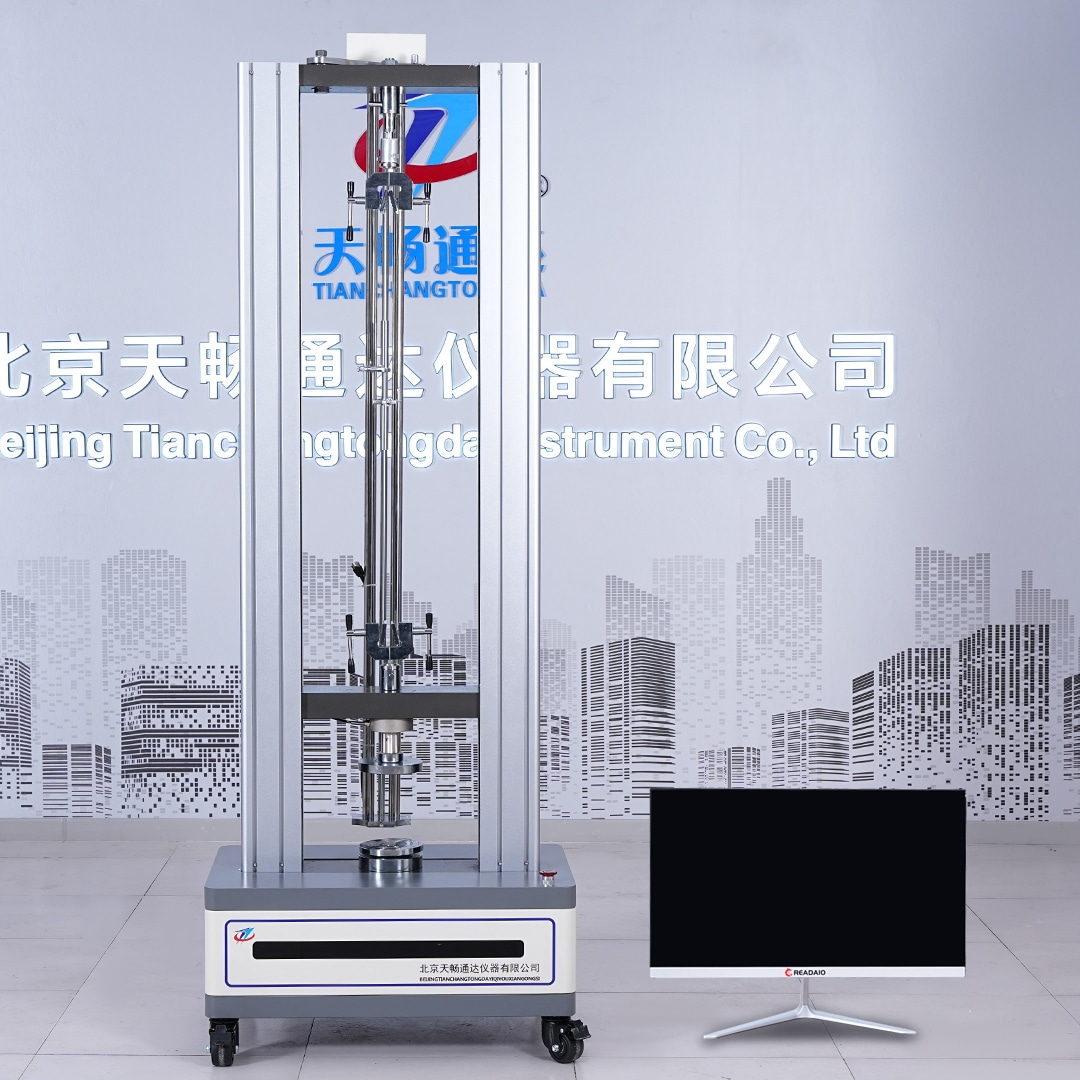

High-precision UTM machine with certified load cell, servo drive, modular grips, and full-featured test software. Designed for professional lab applications.

🔍 View UTM Machine Product Details