📌 1. Failed tensile tester data is often due to non-compliance with applicable standards

When using a tensile tester to evaluate material properties, many operators believe that “if the device runs smoothly and the sample breaks, the test is valid.” However, in reality, the most important factor in determining whether tensile test data is valid lies in whether the test parameters were set in accordance with recognized standards.

Every material category—whether plastic, rubber, metal, or composites—has its own applicable national or international standards. These standards specify critical parameters such as test speed, gauge length, grip type, and failure criteria. If a test is conducted without referencing the appropriate standard, the results may be deemed invalid by clients, laboratories, or certification bodies.

This article introduces 5 of the most widely used and authoritative tensile testing standards to help you identify whether your test was truly compliant.

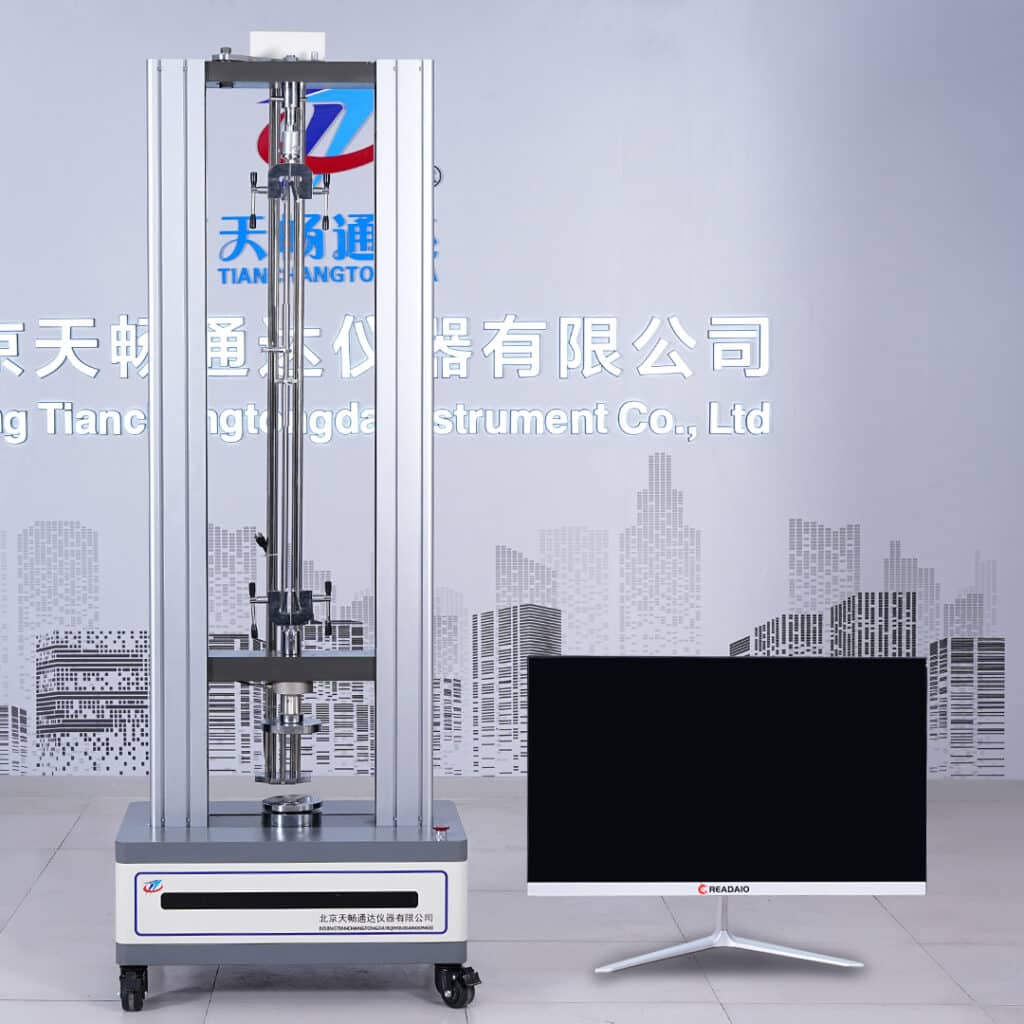

🔧 Tensile Tester

This tensile tester provides accurate force measurement, customizable test speeds, and multiple test templates for compliance with ISO, ASTM, and other standards.

🔍 View Tensile Tester Product Details⚙️ 3. The 5 Most Common Tensile Testing Standards That Determine Data Validity

Here are 5 standards that are widely used around the world and directly impact how tensile test parameters should be set:

- ASTM D638 – Plastics

- Requires a gauge length of 50mm or 25mm

- Different specimen types (Type I–V) call for different speeds

- Most commonly used for general-purpose plastic testing

- ISO 527 – Plastics and composites

- International standard with strict definitions for extensometers, gauge length, and failure judgment

- Requires full stress–strain curve reporting and modulus calculation

📘 ISO 527-1 Official Standard

- ASTM E8/E8M – Metals

- Designed for metallic materials, with requirements for round and machined specimens

- Strong emphasis on elongation after fracture and fracture location

📘 ASTM E8 Standard

- JIS K 6251 – Rubber

- Japanese standard for high-elongation, low-modulus materials like rubber and silicone

- Specifies testing speeds (e.g., 200mm/min or 500mm/min) and requires grip compensation for stretch

- GB/T 1040.2 – Plastics (China National Standard)

- Closely aligned with ISO 527

- Commonly used in domestic reports and national compliance cases

❌ 4. What Happens When You Don’t Follow a Standard?

- Incorrect test speed: Using metal test speed (1mm/min) on plastic materials leads to abnormal break behavior

- No gauge length setting: Elongation cannot be calculated, rendering the test invalid

- Wrong grip type: For example, wedge grips used instead of pneumatic grips cause slippage or break at clamping point

- No record of break location: Some standards consider results invalid if fracture position is not reported

None of these issues are caused by the machine—they stem from incorrect or missing test standards.

📊 5. How to Set Standard Parameters on Your Tensile Tester

Most tensile testers allow you to create and store test templates. You can:

- Set test speed (e.g., 50mm/min for ISO 527)

- Select gauge length (25mm or 50mm)

- Choose output fields such as tensile strength, elongation at break, and curve data

- Save templates for consistent application across batches

Some advanced systems support built-in ASTM, ISO, and JIS templates, which help ensure test repeatability and report compliance.

🧩 6. Compliance Is Not About Force—It’s About Following Standards

Many users report that their tensile tester “works fine but the data is still rejected.” In most cases, it’s not a mechanical issue—it’s a compliance issue.

Examples:

- A plastic film tested under GB/T standard was rejected by a German client due to the lack of ISO 527 compliance

- A third-party lab issued a report that failed audit because it lacked the required failure mode and break point data

Conclusion: A tensile test is not just about applying force—it’s about producing standardized, traceable, and verifiable data.

✅ 7. Final Suggestions: Test Standardization Starts with Awareness

Before using your tensile tester, confirm these three things:

- ✔ Which international/national standard applies to your material?

- ✔ Are your software settings aligned with the standard?

- ✔ Does your exported report include all required fields?

We recommend developing a material–standard–parameter reference chart and training your team to follow template-based procedures. This reduces human error and enhances data credibility.

Not sure which standard applies? Contact us—we provide free technical consultations and testing setup guidance.