When buying a Universal Testing Machine (UTM), one of the biggest questions for international buyers is:

“Should I choose a Chinese manufacturer or stick with international brands like Instron or Shimadzu?”

This article explains the true differences between Chinese-made and international UTM brands, from hardware design to control systems and service support—so you can make a smart, informed decision.

1. Frame Structure: Practical vs Precision-Engineered

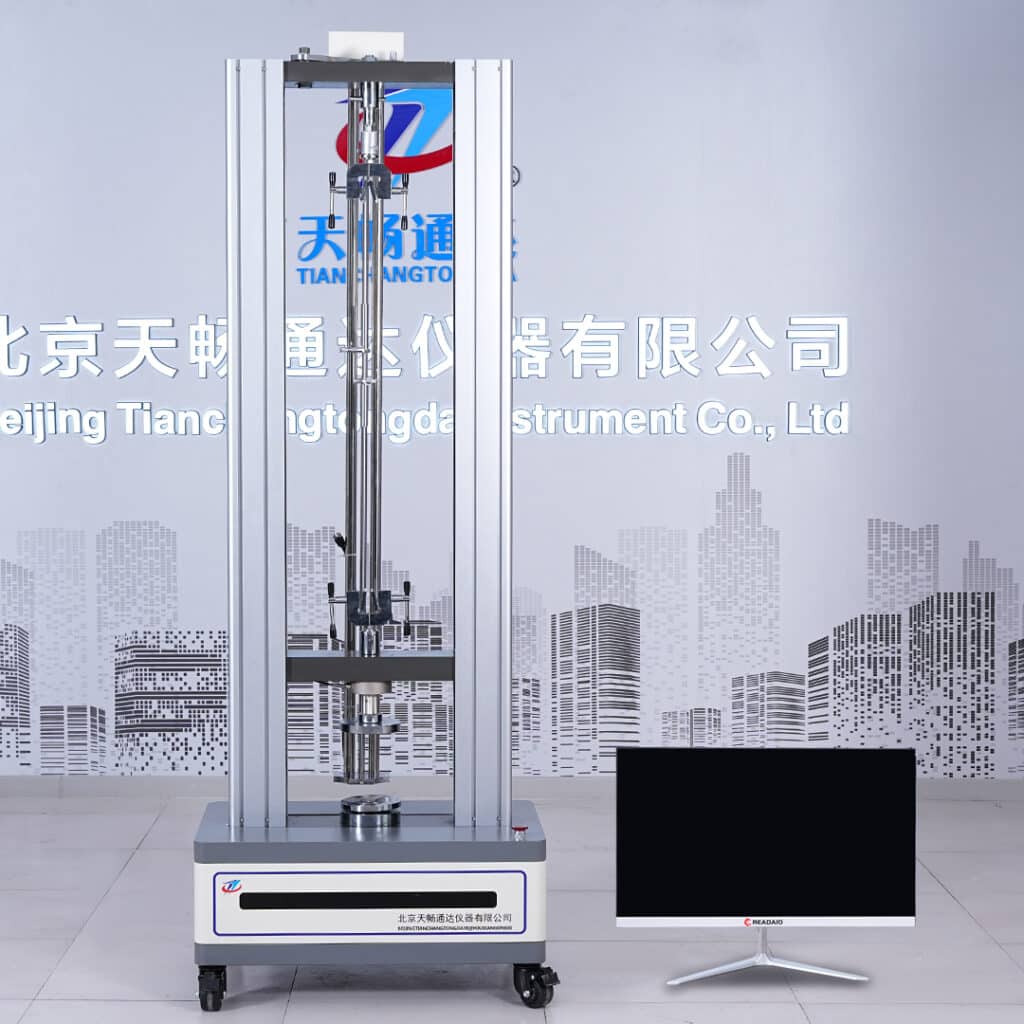

- Chinese brands often use aluminum or steel modular frames, suitable for general applications. Higher-end models offer dual-column or C-frame types with servo-driven crossheads.

- International brands typically use rigid casted single-piece frames. These offer better alignment, high-frequency stability, and are built for long-term durability.

Verdict: If you need stable long-duration tests or dynamic fatigue testing, international brands win. For routine tensile tests, Chinese frames are sufficient.

2. Control System & Sensors: Testing vs Controlling

- Chinese systems typically offer open-loop or semi-closed-loop control with 10–50Hz data acquisition. Force accuracy is within ±1%.

- International systems feature high-speed closed-loop PID control, real-time feedback, and sensor accuracy of ±0.5% or even ±0.25%.

Verdict: For high-precision labs and certified test reports, international brands are preferred. But for in-house quality control or education, Chinese systems perform well.

3. Software Capabilities: Test Tool or Full Data Platform?

- Chinese UTM software focuses on basic testing modes (tensile, compression, bending), with Excel/PDF report export. Interface is often simple, with limited programming.

- International software supports multi-language interfaces, sequence programming, real-time monitoring, automated report creation, and even integration with LIMS or MES systems.

Verdict: If your workflow requires customizable automation, scripting, or compliance reports, international software adds real value.

4. Long-Term Ownership Cost

While Chinese UTMs have lower initial cost (30–60% less than global brands), long-term factors include:

- Shorter calibration cycle and higher sensor replacement rate

- Lower software upgradability

- Downtime risk if local support is unavailable

International UTMs typically offer longer service life, stable calibration, and guaranteed parts supply for over 10 years.

Verdict: For budget-sensitive, short-term needs, Chinese machines are cost-effective. For R&D or external certification labs, international brands may cost less over time.

5. Service, Manuals, and Certification Support

| Factor | Chinese Brands | International Brands |

|---|---|---|

| Installation & Training | Remote or basic onsite | Local engineers, full training |

| Documentation | Chinese + partial English | Full CE/ISO docs, manuals, calibration sheets |

| Export Experience | Some support export | Fully compliant with EU/US procurement standards |

Verdict: If you’re buying for export, OEM production, or accredited labs, ensure the supplier provides certification-ready documentation and after-sales training.

📌 Summary Table:

| Feature | Chinese UTM | International UTM |

| Frame | Modular / cost-efficient | Cast frame / rigid / precise |

| Force Accuracy | ±1% | ±0.5% or better |

| Software Function | Basic test + export | Multi-language, programmable |

| After-sales Support | Partial / remote | Local + long-term service |

| Price Range | $2,000 – $8,000 | $10,000 – $30,000+ |

| Best For | QC testing, training, OEM | Research labs, certification |

🔗 Related Product:

👉 Explore our Universal Testing Machine models here

📩 Not Sure Which Brand Fits Your Needs?

We can help you evaluate your testing requirements and recommend the best model—whether you need a Chinese machine for general testing or an internationally certified system.

👉 Contact us directly via WhatsApp and get a detailed configuration quote within 24 hours.