In modern materials engineering, Universal Testing Machines (UTMs) are widely used to evaluate mechanical properties such as tensile strength, elongation, compressive load, and modulus of elasticity. While UTMs are often associated with metals, they are equally critical for testing non-metallic materials such as plastics, rubber, composites, and foam.

This guide will show you how to properly use a Universal Testing Machine to test non-metallic specimens, focusing on both tensile and compression procedures, equipment setup, and international testing standards.

✅ Why Test Non-Metallic Materials?

Non-metallic materials are widely used in industries such as automotive, packaging, construction, and medical devices. Unlike metals, they exhibit nonlinear stress-strain behavior, are more sensitive to strain rate, and often deform under lower loads.

Testing these materials requires precision tools and adherence to standardized procedures. A UTM provides the necessary force application and data capture mechanisms to deliver reliable results.

🔧 Required Setup for Non-Metallic Tensile Testing

- Appropriate Load Cell

Most non-metallic materials require low-capacity load cells (0.5kN–5kN). Using an oversized cell (e.g., 50kN) reduces resolution and leads to inaccurate force readings. - Specialized Grips

- Rubber and elastomers: Use pneumatic grips to avoid slippage.

- Thin plastics or films: Use grips with rubber face or vice-type tension fixtures.

- Avoid metallic serrated jaws unless the standard explicitly allows it.

- Test Speed

Test speed significantly affects soft materials. For instance, per ASTM D638, rigid plastics require a crosshead speed of 5 mm/min, while films may require up to 500 mm/min. - Sample Conditioning

Environmental control is critical. Precondition materials at 23 ± 2°C and 50 ± 5% RH before testing, especially for polymers and foam.

🧪 Performing a Compression Test on Non-Metals

Compression tests for foam, rubber, and composite blocks reveal deformation behavior, compressive strength, and modulus.

- Fixtures: Use flat platens with self-alignment to ensure uniform load application.

- Standards: Follow ISO 604 for plastic compressive tests, or ASTM D695 for polymers.

- Control Mode: Use displacement control when stiffness is low.

📊 What Results Are Typically Obtained?

From both tensile and compression tests, the UTM delivers:

- Tensile strength (MPa or psi)

- Elongation at break (%)

- Compressive strength

- Young’s Modulus (Elastic Modulus)

- Yield point (for rigid polymers)

All results can be exported in .csv or .pdf format via testing software and used for product validation, supplier evaluation, or academic research.

📏 Example Application: Rubber Seal Testing

Let’s take an automotive rubber gasket as an example. Using a 2kN load cell, pneumatic grips, and ASTM D412 standard, the UTM can measure:

- Maximum elongation

- Tear resistance

- Load vs extension curve

This data helps ensure the material won’t fail under dynamic sealing conditions.

🔗 Related Product:

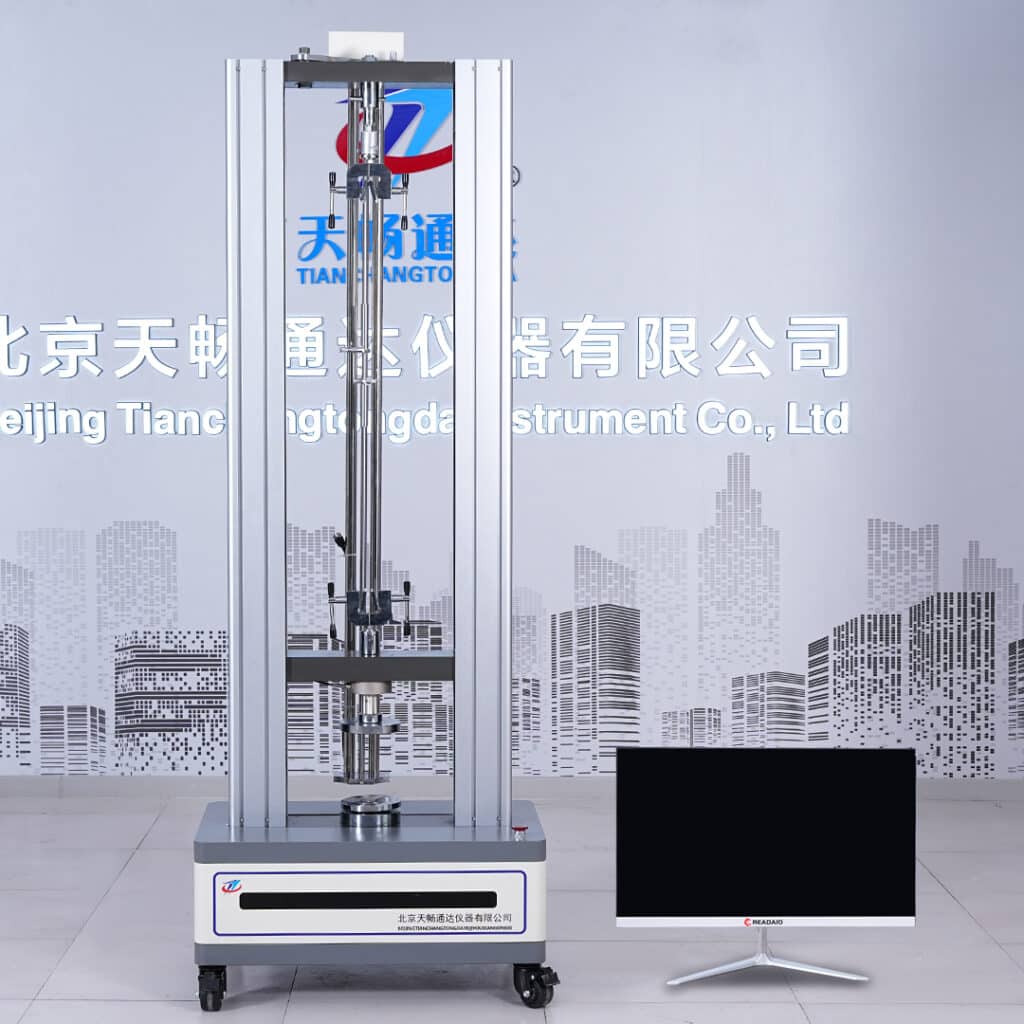

If you’re looking for a UTM model specifically designed for non-metallic testing (rubber, plastics, composite samples), check out our product page:

👉 Universal Testing Machine – Non-Metal Series

❗ Common Testing Mistakes to Avoid

- Using the wrong grip type (causing sample slippage)

- Ignoring temperature conditioning

- Selecting inappropriate test speeds

- Forgetting to calibrate load cells for low-force ranges

- Running without an extensometer when measuring modulus

✅ Final Recommendations

A Universal Testing Machine is a highly versatile tool. When configured correctly, it can produce highly reliable results even with the most flexible, brittle, or layered non-metal materials.

To maximize accuracy:

- Always follow ISO/ASTM standards.

- Select the correct fixtures for each sample type.

- Calibrate load cells regularly.

- Record ambient temperature and humidity for traceable reports.

📣 Ready to Start Testing?

Need guidance on selecting the right UTM configuration? Or want a quote based on your testing requirements?

👉 Click here to get a custom solution from our team.

Whether you’re in R&D or quality control, we’ll match your materials to the right machine — accurately, efficiently, and affordably.