📌 Introduction: UTM Machines—Essential, But Often Misunderstood

If you work in product development, quality control, or material R&D, you’ve likely heard the term UTM machine—short for Universal Testing Machine. But what exactly is it? What can it do? And why do almost all testing labs have one?

In this article, we’ll break down what a UTM machine is, what types of materials and properties it can test, and why it’s considered the backbone of modern materials testing.

🔍 What Is a UTM Machine?

A UTM machine (Universal Testing Machine) is a highly versatile device used to determine the mechanical properties of various materials. Despite the name, “universal” doesn’t mean it can test everything—it means it supports multiple test types, including:

- 🔹 Tensile testing

- 🔹 Compression testing

- 🔹 Flexural/bend testing

- 🔹 Shear strength

- 🔹 Peel and adhesion testing

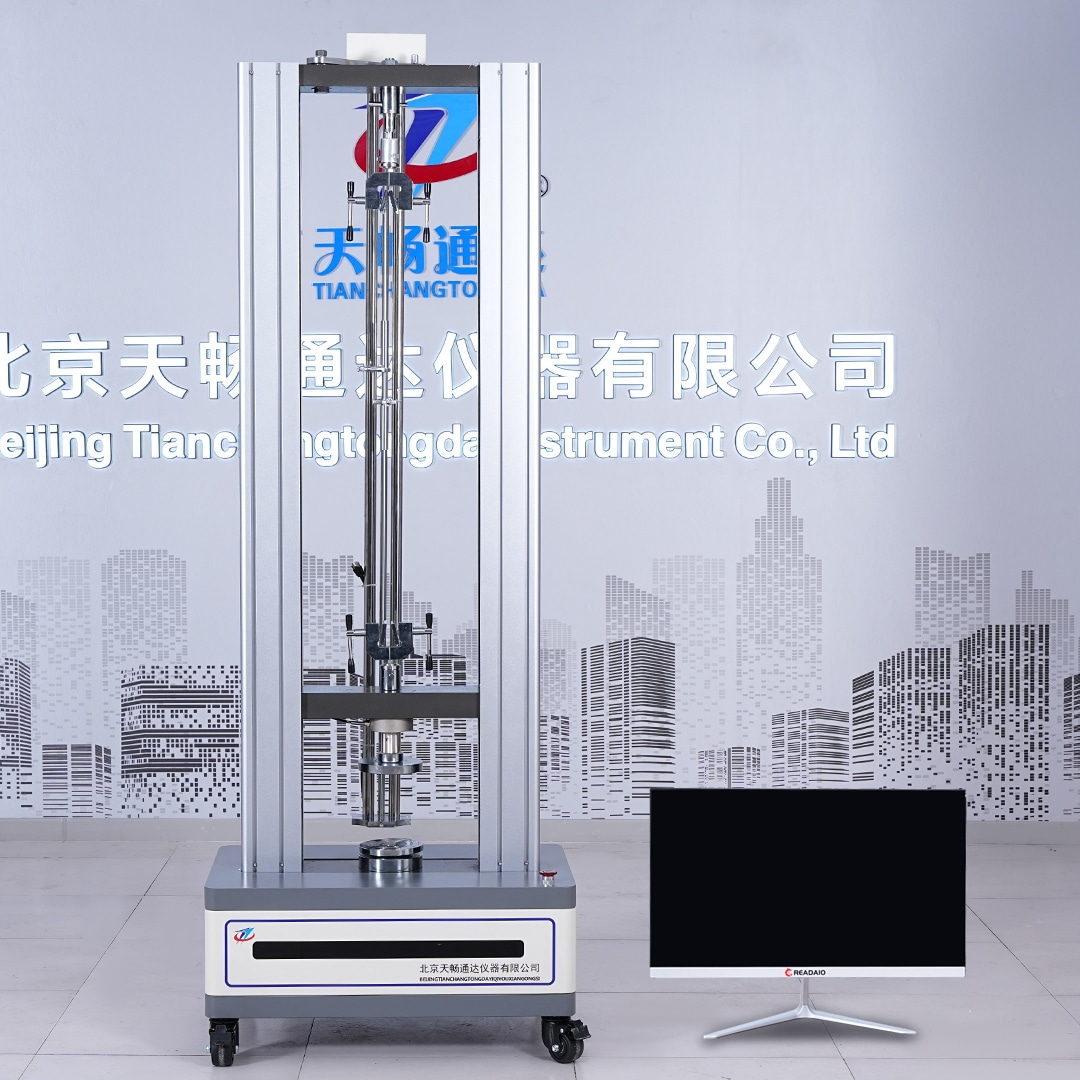

UTMs typically consist of:

- A loading frame with movable crosshead

- Interchangeable grips and fixtures

- A load cell for force measurement

- A displacement measurement system

- Computer-controlled software for test execution and data analysis

🧪 What Can a UTM Machine Test?

Here’s a quick breakdown of the types of tests a UTM machine supports—and what they’re used for:

| Test Type | Purpose | Typical Materials |

|---|---|---|

| Tensile Test | Measures breaking force and elongation | Plastics, metals, elastomers |

| Compression Test | Evaluates how materials deform under pressure | Foams, ceramics, paperboard |

| Flexural Test | Determines bending strength and stiffness | Composites, plastic sheets |

| Shear Test | Assesses shear resistance or bonding strength | Adhesives, bonded laminates |

| Peel Test | Measures adhesive strength of layers | Labels, tapes, flexible films |

📌 Depending on the grips and software, a single UTM machine can be adapted to handle dozens of test standards across multiple industries.

🏭 Which Industries Use UTM Machines?

UTM machines are used in nearly every industry where material properties matter. Typical use cases include:

- Universities and Research Labs

→ Curriculum experiments, new material studies, graduate theses - Plastics and Rubber Manufacturers

→ Incoming raw material inspection, batch QC, performance benchmarking - Aerospace and Automotive

→ Component testing for structural strength and safety standards - Medical Devices and Packaging

→ Evaluation of suture strength, medical tubing, seals, blister packs - Construction and Civil Engineering

→ Concrete cylinder compression, rebar tensile strength, bonding tests

📎 Whether you’re testing soft foams or high-strength carbon fiber, a UTM machine can be configured to support your application.

📈 Why Is a UTM Machine So Essential?

A UTM machine is often the first and most foundational testing instrument in any mechanical lab. Here’s why:

- 🔧 Versatility – One machine, many tests

- 💻 Software Control – Digital analysis, curves, automatic reports

- 🔁 Scalability – Supports future upgrades and new standards

- 💡 Standards Compliance – Meets ASTM, ISO, GB and other global test protocols

Without a UTM machine, most labs can’t even begin to verify tensile strength, elasticity, stiffness, or failure points—all fundamental to product certification and R&D.

📚 Standards and Compliance

A well-configured UTM must be capable of performing tests in accordance with major global standards. Two of the most common include:

📌 Any data generated without following these standards may be rejected by clients, certifying bodies, or regulatory agencies.

✅ Final Thoughts: It’s Not Just a Machine—It’s Your Testing Backbone

A UTM machine isn’t just equipment—it’s a lab’s most critical investment in data accuracy, repeatability, and long-term credibility.

Whether you’re a lab technician, engineer, or purchasing manager, understanding the value and role of a UTM machine ensures you choose the right configuration for your current and future testing needs.

📞 Need help selecting the right model? Our technical team can assist with load range analysis, fixture compatibility, and standard matching.

Precision UTM machine for tensile, compression, bending, and shear testing. Ideal for labs and industrial R&D with ISO/ASTM compatibility.

🔍 View UTM Machine Product Details