📌 Introduction: Choosing the Right UTM Machine Starts with the Right Comparison

When purchasing a UTM machine, international buyers often face a critical decision—whether to choose a well-known imported brand or consider a high-quality domestic model, often made in China.

On paper, both types of machines can meet standard requirements. But what about long-term accuracy? Maintenance? Spare parts? In this guide, we break down the real-world differences between domestic and imported UTM machines in terms of performance, durability, and total cost.

⚙️ Performance: Are Domestic Machines as Precise as Imported Ones?

| Feature | Imported UTM Machines | Domestic UTM Machines (China) |

|---|---|---|

| Load Measurement Accuracy | Class 0.5 (±0.5%) or better | Class 1 or 0.5 depending on configuration |

| Software Capabilities | Full-featured but often complex | Simple interface, multilingual, customizable |

| Multi-Test Support | Expandable to fatigue, torsion modules | Includes tensile, compression, flexural standard |

| Motion System | High-end servo motor with closed-loop | Chinese or hybrid servo systems with high repeatability |

✅ Many labs report that Chinese machines meet test standards well—especially when paired with calibrated load cells and good software.

🧱 Durability and Maintenance: Lifespan Isn’t Just About Years

| Feature | Imported Machines | Domestic Machines |

|---|---|---|

| Average Service Life | 12–15 years | 10–12 years with proper use |

| Spare Parts Availability | OEM-only; longer shipping times | Standardized components; locally serviceable |

| Software Licensing | Often requires annual renewal | Permanent license, with optional upgrades |

| Remote Support | May require certified technician visits | Remote video training and real-time support |

✅ Domestic machines offer better flexibility in self-maintenance, especially in developing countries or regions lacking local distributors.

💰 Price Breakdown: How Much Are You Really Paying?

| Feature | Imported Machines | Domestic Machines |

|---|---|---|

| Typical Price (5kN system) | $15,000 – $35,000 | $3,000 – $7,000 |

| Licensing Fees | Often bundled or separate | Included in base price |

| Grip Accessories | Sold separately in many cases | Often included as standard |

| Calibration Costs | Requires certified third-party calibration | Local calibration or in-house options |

✅ For labs on a tight budget, domestic UTMs can offer up to 70% savings with no major loss of core functionality.

🧪 Case Study: A European Plastics Lab Switched to a 5kN Domestic UTM

One of our European clients, a university testing plastics film, originally used a German-brand UTM. After upgrading to a 5kN Chinese-made model with full software access and remote support, they reported:

- 40% faster setup time

- Easier report generation (direct Excel + PDF output)

- Over 70% cost savings over a 3-year span

📎 This reflects a growing trend: performance parity is achievable—and budget flexibility is often critical for small and medium labs.

📚 Standards Compatibility: Yes, Domestic UTMs Can Meet ISO/ASTM

All reliable UTM machines—domestic or imported—must comply with international force verification standards. The two most referenced include:

- ISO 7500-1:2018 – Verification of Force Measuring Systems (ISO.org)

- ASTM E4 – Force Verification Overview (Wikipedia)

✅ Our machines support full English UI and allow switching between ISO, ASTM, GB, and JIS test standards as required.

✅ Final Thoughts: It’s Not About Country—It’s About Suitability

Buying a UTM machine isn’t about choosing East or West. It’s about matching your testing needs with the right system in terms of:

- Accuracy

- Long-term serviceability

- Price-performance ratio

- Standards compliance

📞 If you’d like help evaluating whether a domestic or imported machine is best for your needs, contact our technical team for a no-obligation consultation.

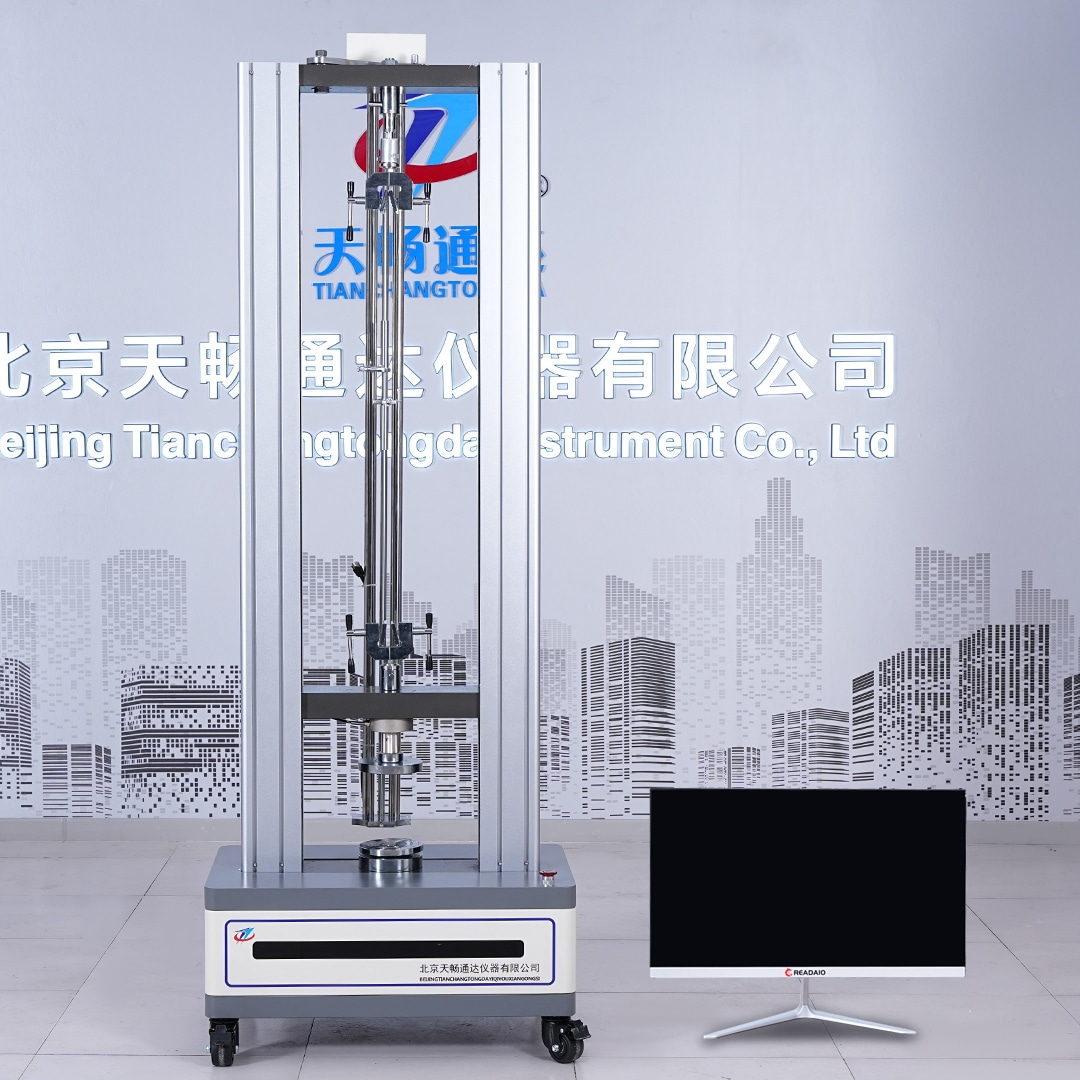

Cost-effective UTM machine with ISO/ASTM compliant accuracy, remote support, and modular design. Ideal for labs seeking reliable performance on a budget.

🔍 View UTM Machine Product Details